Industry 4.0 Predictive Analytics and Machine Learning Reduce Downtime with Data Analytics for Predictive Maintenance

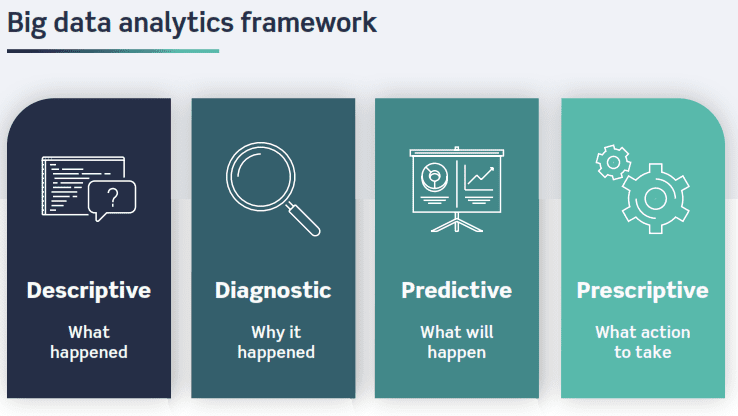

The amount of data we have today, and the ease of access allow us to utilize this data in ways that were not previously possible. One of these ways is to optimize our maintenance activities by analyzing our predictive and preventive maintenance activity data.

Identifying failures through communicating with our industrial machines has now become easier than ever, this allows us the opportunity to determine failure patterns and their progression over time, finding root causes of failures in a more reliable and easier fashion and better defining failure rates of equipment and components allowing a more optimized range of activities.

It is well documented that the earlier we detect issues the better opportunity we have at not allowing them to reach terminal or catastrophic failure points and the better we can plan for outages to replace or repair these issues. This is becoming more accurate and simpler to do using analytics for predictive and preventive maintenance activities.

The training course exists of 5 modules and an assignment in 3 days. Participants will learn how to use data analytics to be able to monitor and predict maintenance needs. In addition, to be knowledgeable of the required processes and phases from data preparation up to interpretation and presentation of the findings.

Results

- Know the definition and applications of data analytics for maintenance and to use them in practice.

- Know how to prepare for n implementation by setting objectives, use of tools, create a plan of action and design the working process.

- Sufficient knowledge to explore the different opportunities, tools, and methods.

- Know the different maintenance methods and how to make the next steps in more data-driven maintenance.

- Know on a high level how to translate data into results and to present these in a report and/or action plan.

Learning Objectives

During the workshop attendees will learn:

- The latest asset monitoring techniques and which combination of techniques is most suitable for each equipment type.

- Failure degradation mechanisms and their corresponding maintenance strategy.

- Using predictive maintenance techniques, how to identify specific degradation mechanisms and develop their P-F curve and P-F Interval prediction.

- Utilizing operational and maintenance data to identify potential issues with machines.

- Understand Support Vector Machine (SVM) Algorithm, Neural Networks, and Regression Method.

- Developing the most optimized set of countermeasures for identified failures to reduce or illuminate them or their impact.

- Achieving the maximum benefit from your digitized monitoring and computerized maintenance management systems data.

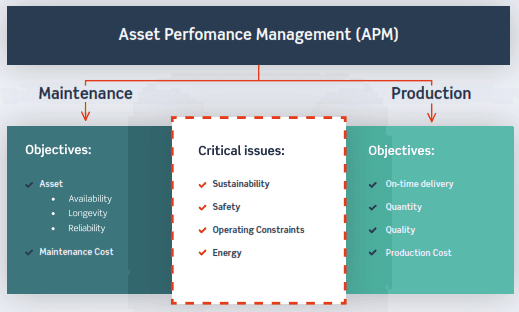

- Developing availability simulation models and selecting optimal activities and their intervals using APM Studio by UReason.

Join us on our upcoming course:

Industry 4.0 Predictive Analytics and Machine Learning

Dec. 1-3, 2021 via VILT

Send us an email: info@erudite.com.ph