Hybrid Training | In-Person and VILT

Five Pillars in Maintenance and Reliability Excellence

August 6-9, 2024

Risk and Asset Management Review based on CAMA BoK (ISO 5500x | ISO 31000)

August 12-14, 2024

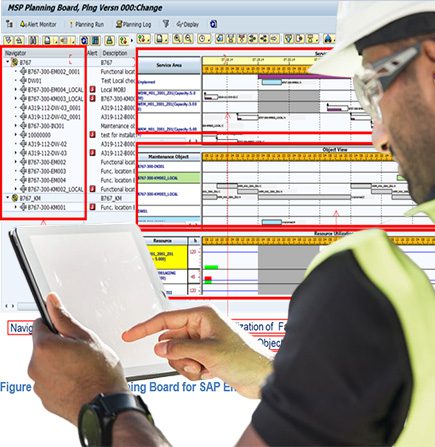

Maintenance Planning and Scheduling Excellence Course

August 22-23, 2024

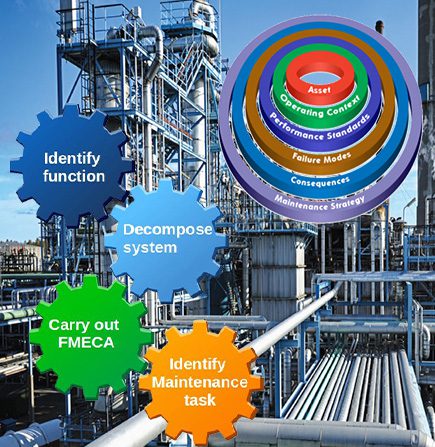

Applied Reliability Centered Maintenance

August 28-30, 2024

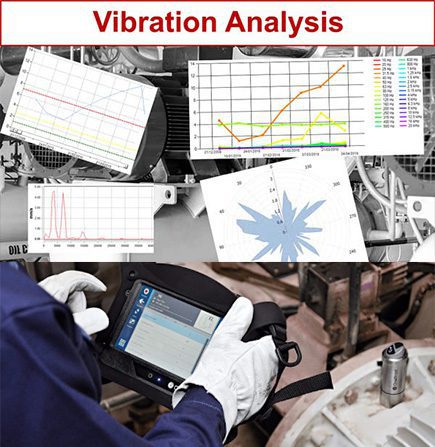

Cat. 2 Basic Machinery Vibrations Preparation Course

September 9-13, 2024

MRO Storeroom Control and Optimization

September 16-18, 2024

Our Valued Clients

Latest Articles

Global Maintenance Day 2023

Erudite Reliability Services OPC joins hands with the Global Forum to emphasize the significance of maintenance in sustaining the functionality and resilience of our society. Together, we highlight the critical role maintenance technicians play in ensuring the seamless operation of industries and the well-being of individuals worldwide. It is a chance to raise awareness among the general public about the intricate work that goes into maintaining our infrastructure and the constant pursuit of excellence in this field.

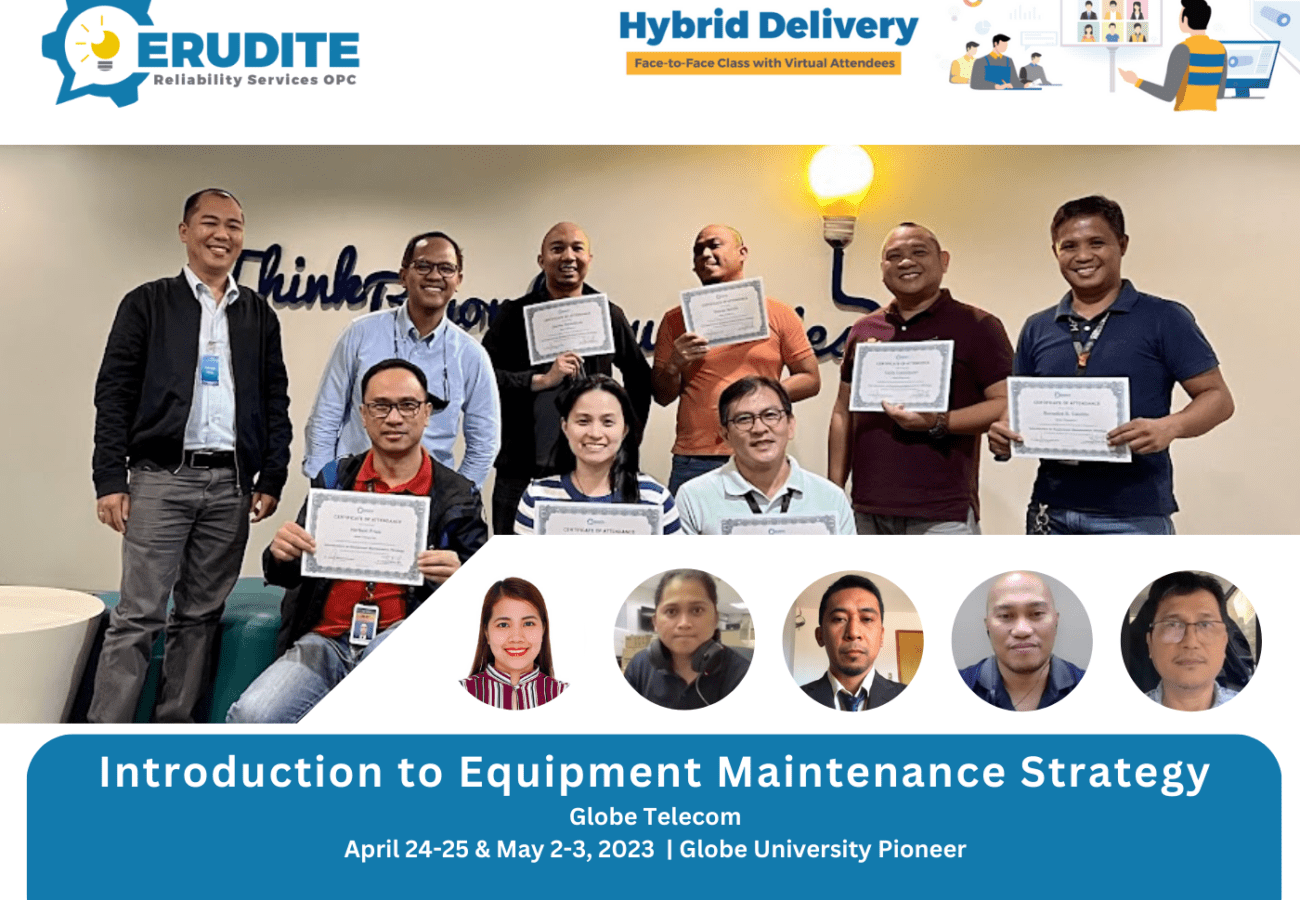

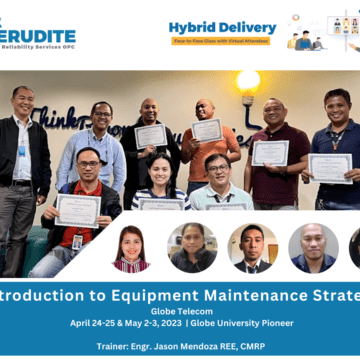

Featured Article: Successfully Concluded Training Event on Introduction to Equipment Maintenance Strategy

Globe Telecom’s commitment to excellence was exemplified by their investment in professional development through this training program. The successful conclusion of the Introduction to Equipment Maintenance Strategy training signifies the organization’s dedication to continuous improvement and operational excellence in the maintenance domain. Armed with standardized maintenance strategies and a comprehensive understanding of RCM, FMEA, and PM Optimization, participants are now equipped to enhance equipment performance, minimize downtime, and extend equipment lifespan. The training event stands as a testament to Globe Telecom’s proactive approach towards achieving excellence in equipment maintenance practices and furthering the organization’s overall success.

ISO 55000 Standard for Asset Management

Assets, and the value realized from them, are the basis for any organization delivering what it aims to do. Whether public or private sector, and whether the assets are physical, financial, human or ‘intangible’, it is good asset management that maximizes value-for-money and satisfaction of stakeholders’ expectations. It involves the coordinated and optimized planning, asset selection, acquisition/development, utilization, care (maintenance) and ultimate disposal or renewal of the appropriate assets and asset systems. Insights into the integration and optimization of asset management have developed since the 1990s (from the North Sea oil and gas industry and the Australian public sector), to identify a range of essential business processes, alignment activities and system integration features that yield very significant performance benefits.

Revolutionize Your Problem-Solving Approach with the ARCA Methodology & RC Pro™

Erudite Marketing Team successfully conducted a webinar on Effective Problem-Solving Methodology – Apollo Root Cause Analysis and RC Pro™ Software that introduced participants to the ARCA methodology and RC Pro™ software. A new way of thinking in solving problems of all types using the Cause and Effect Principles. During the session, attendees learned about the ARCA methodology and received a PDF copy of “Seven Steps To Effective Problem-Solving and Strategies for Personal Success by Dean Gano”.

SUBSCRIBE FOR LATEST UPDATES