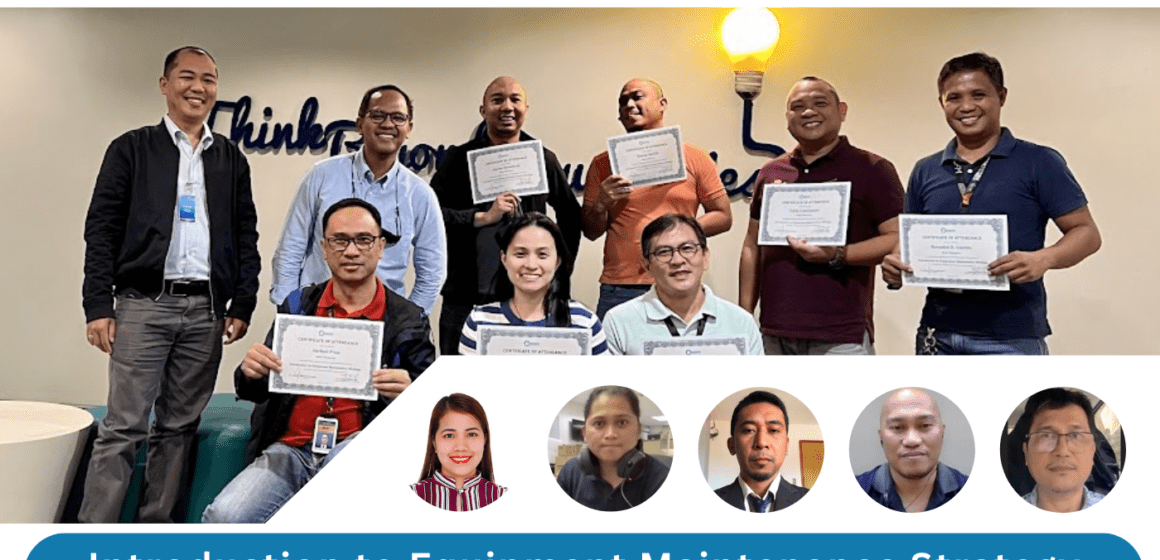

Global Maintenance Day 2023

Erudite Reliability Services OPC joins hands with the Global Forum to emphasize the significance of maintenance in sustaining the functionality and resilience of our society. Together, we highlight the critical role maintenance technicians play in ensuring the seamless operation of industries and the well-being of individuals worldwide. It is a chance to raise awareness among the general public about the intricate work that goes into maintaining our infrastructure and the constant pursuit of excellence in this field.